DIGITAL TWINNING EXAMPLES

Challenges | Solutions | Results

How to reach 99% auto rate – ARV fleet optimization

Challenges

Originally fully automated factory turning into human logistics support

Increasing product types, but constant output

High traffic and ARV blocking ending in underutilized machines

Solution

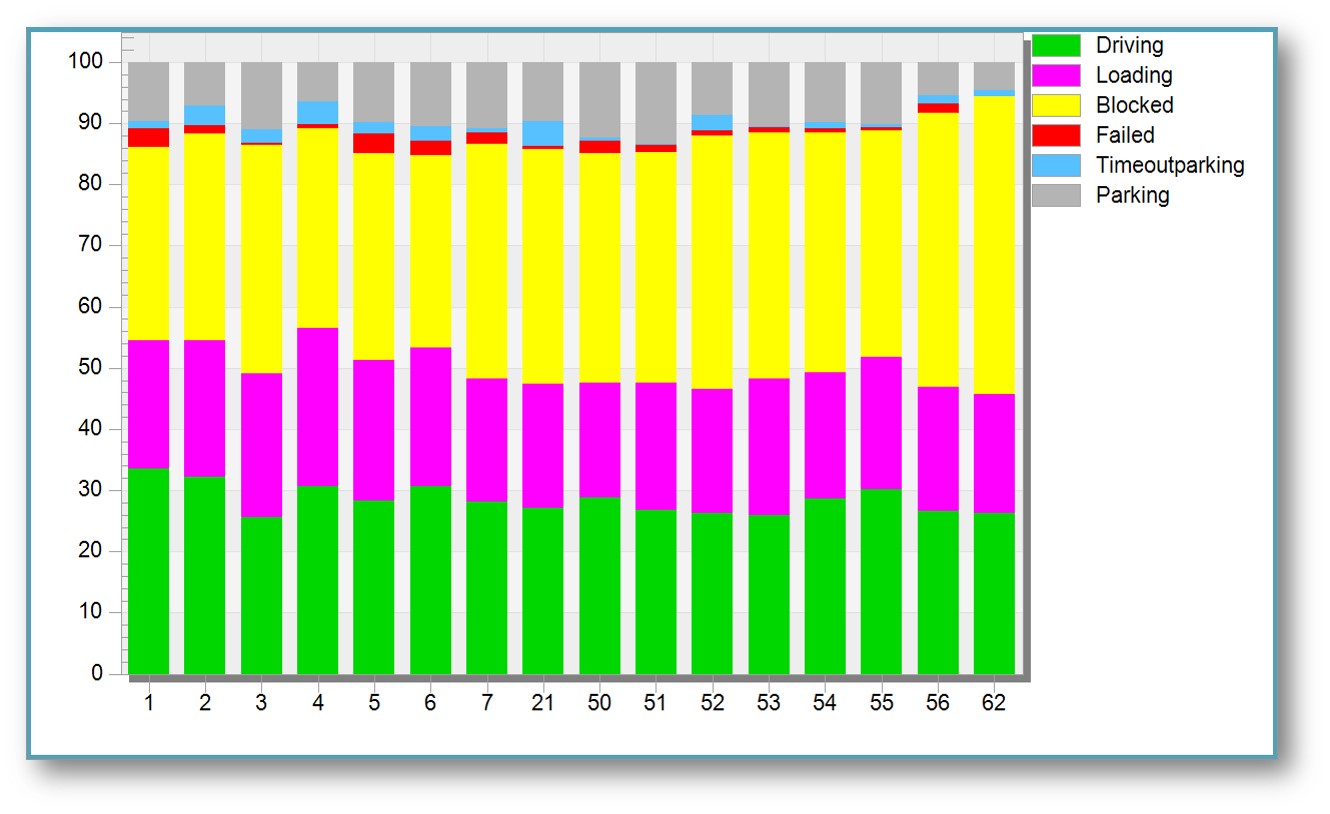

- Experiments with different task distribution logics

- Analyzing task lead times, monitoring ARV and machine utilizations

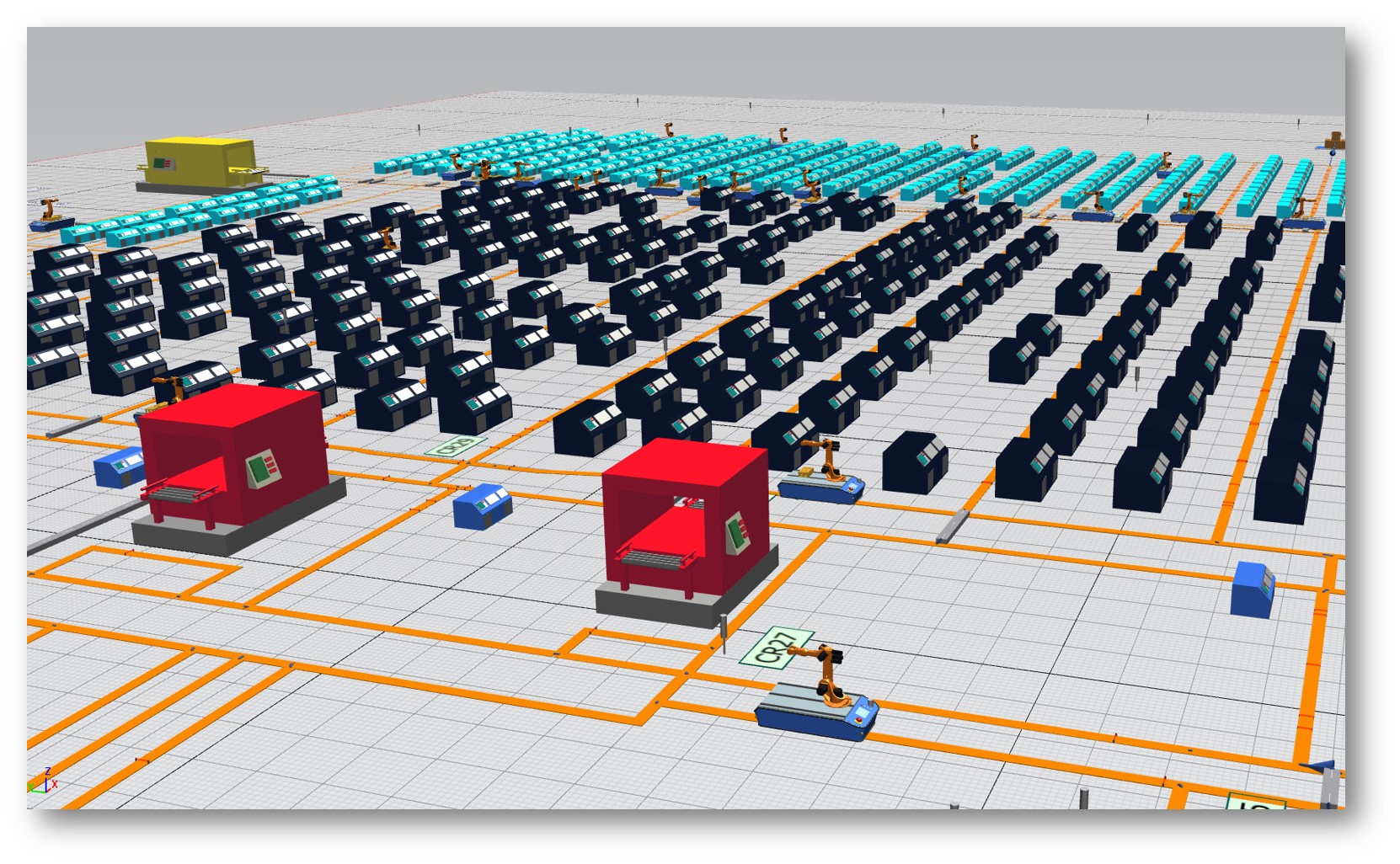

- Detailed execution and control with digital twinning

Results

Auto rate: +9% improvement – now 99%

Finished tasks: 20% improvement

Lead and task duration time: ~ 30% reduction

ARV fleet: 2 ARVs can be allocated to other areas