SOLUTIONS

We can really improve the efficiency of your production

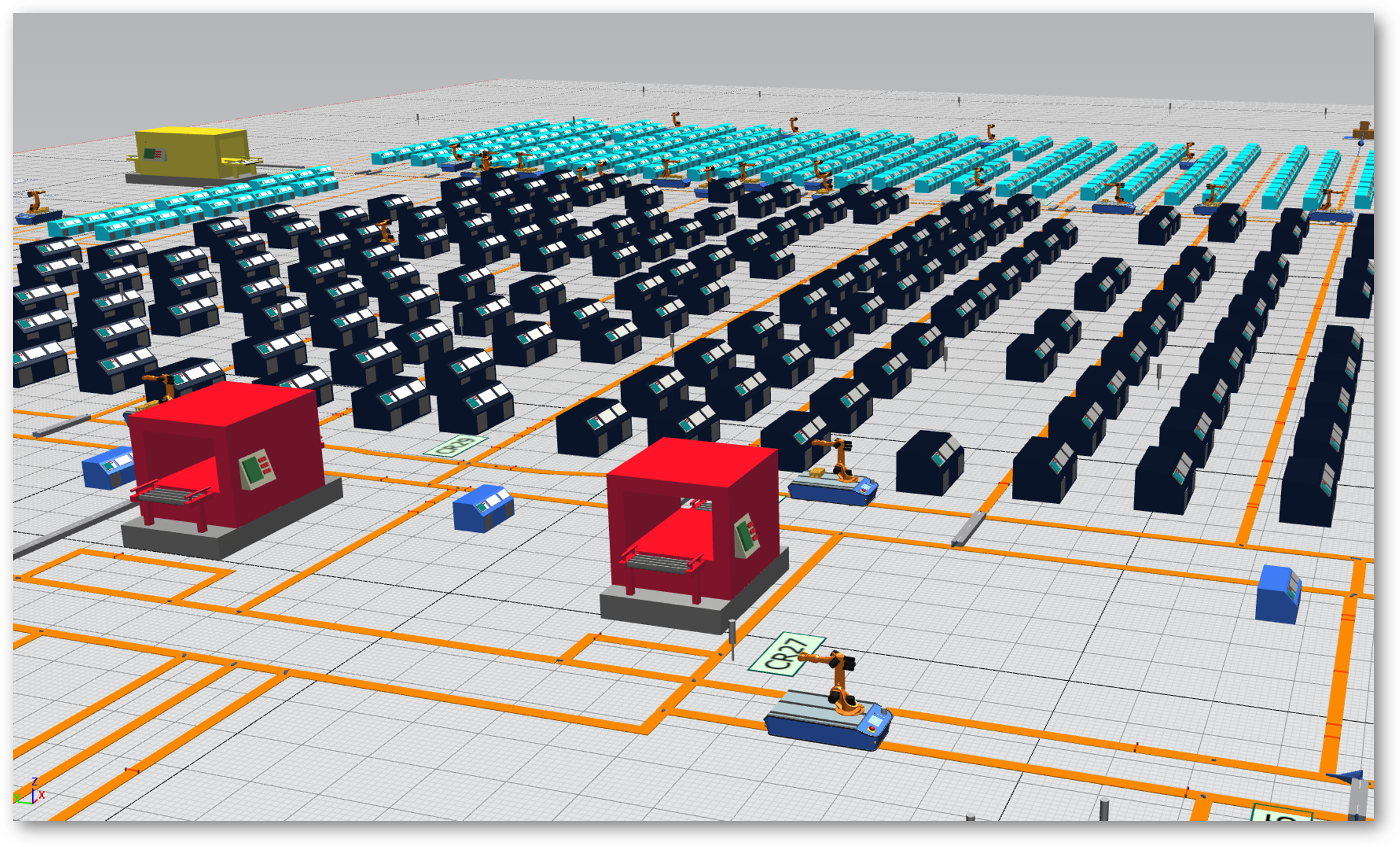

ANALYSIS AND OPTIMIZATION OF MANUFACTURING AND LOGISTICS PROCESSES

Today’s state-of-the-art simulation and data analysis softwares and low-cost computing capacity allow detailed testing and optimization of highly complex production systems. In the field of manufacturing and logistics, simulation modeling and the related detailed data analysis, in which we have decades of experience and significant references, offer the following possibilities:

- Digital twinning, manufacturing and logistics simulations

- Detection of weak points such as bottlenecks or unused capacities

- Validation of system designs or control policies

- Comparative study of the impact of different solutions or investments

- Analysis of the “what-if-if” behavior of the modeled system in an uncertain environment (eg failures, sequence changes, uncertain operation time, etc.)

ADVANCED PRODUCTION PLANNING AND SCHEDULING

Customer-centric production enterprises need production management tools to ensure a high level of customer service while minimizing production costs and handling production fluctuations. In today’s complex and rapidly changing environment, it is crucial to have real-time, integrated use of advanced production management tools (production planning, scheduling, and production management) and supportive IT systems. Building on the many years of professional experience of our staff, EPIC InnoLabs provides the following services and enhancements for the design, implementation and successful integration of the above systems:

- Analysis and modeling of business, production and logistics processes

- Assessment of existing enterprise information architecture (ERP, PPC, APS and MES)

- Selection and/or implementation of target optimization software

- Unique, problem-specific, enterprise-specific application development

INDUSTRIAL DATA ANALYTICS, MACHINE LEARNING AND DASHBOARDING SERVICES

With the development of information and communication technologies, more and more data is being created in the operating and business management systems of companies, the proper use of which is a key part of increasing efficiency and competitiveness. Using the results and tools of data science, Artificial Intelligence (AI) and Machine Learning (ML), problems that could not be solved before can now be solved: processing large amounts of data from complex production systems, data-based statistical conclusions, correlations and predictions give an accurate picture of the system and its processes. These all can be used to support production execution, production planning or business strategy decisions efficiently and objectively. In the field of data analysis-based decision support, our innovation center provides support in the form of the following activities and services:

- Development of Big Data processing and analysis technologies

- Data analytics, determining the relationships between stored data and the manufacturing process

- Contextual search among production data using mathematical and machine learning algorithms

- Predicting and forecasting, exploiting information, and providing feedback on new information discovered

- Definition, description and modeling of production problems, tasks

- Data quality improvement and data integration